Contact us

If you have any questions or would like assistance, please contact our technical team:

- Email: technical@netweber.co.uk

- Telephone: (01525) 722 100

Our technical team is available Monday to Friday, 8:30am until 5.00pm.

We do not recommend rendering over existing render (site batched or manufactured systems) due to the large amount of unknown factors regarding suitability for new render. As explained in greater detail below, these unknown factors include the strength, bond, thickness and quality of the existing render, as well as any existing applied surface treatments which could affect the adhesion of the new render.

Instead, we recommend to either use a decorative finish over the existing render or remove and replace the existing render, however this may result in damage to the substrate.

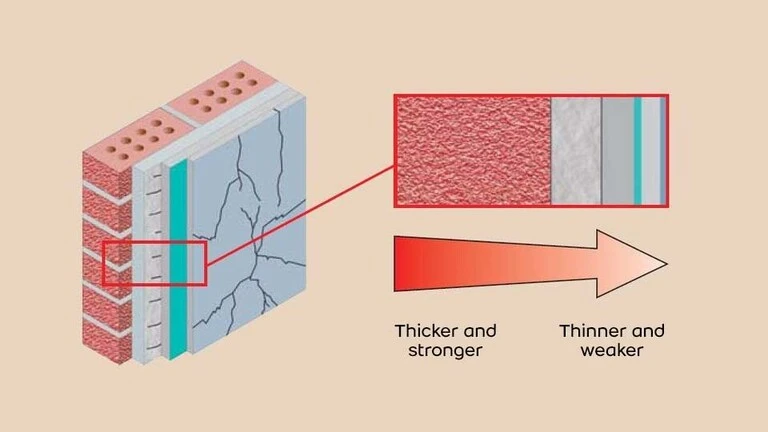

Traditional multi-coat render systems are applied in successive layers which become thinner and weaker towards the surface. Top coat renders therefore may be relatively weak and it is difficult to determine the bond strength of the existing layers of render.

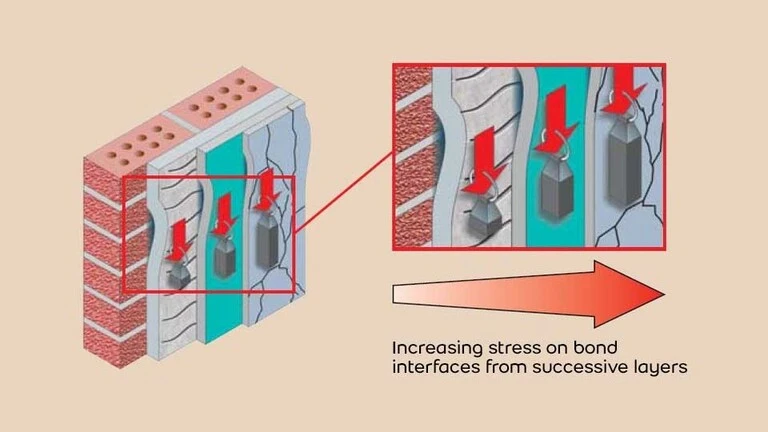

Each layer of render adds more weight to the previous layer(s), negatively impacting on the overall bond strength between layers of render, and between the render and the substrate.

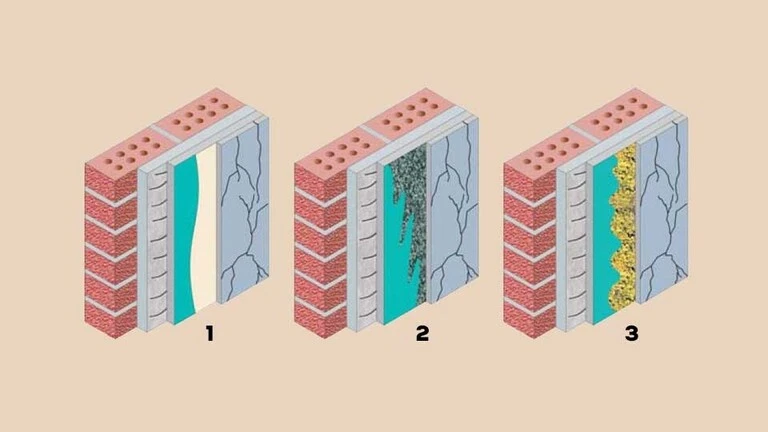

1. Existing renders are often finished with a thin coating or paint which will form a weak interface which is not suitable for rendering over.

2. Dirty deposits accumulated over a period of time can form a weak intermediate layer that interferes with the development of the bond of newly applied render.

3. Organic growth, even though it may be brushed from the surface, remains in the pores of the substrate and can continue to grow, delaminating the new render from the substrate.

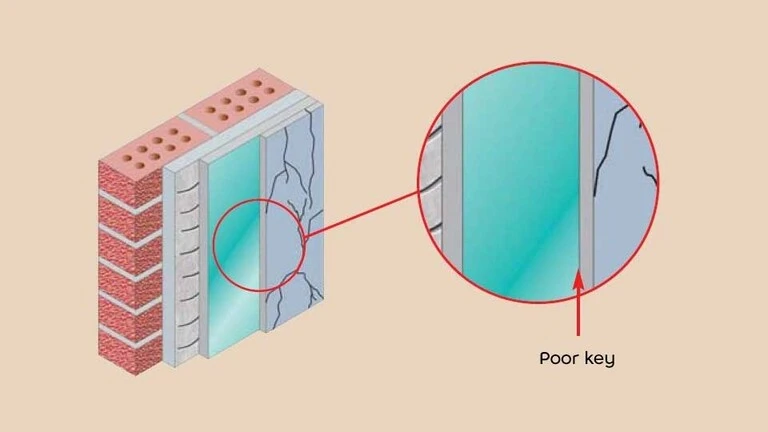

Renders need a combination of mechanical key and suction to bond to the wall. Existing render surfaces, even though unpainted or coated, are usually 'plain face' and seldom have sufficient key to hold a new render.

Additional coats of render can only be applied safely when the existing work is sound and has satisfactory adhesion over the whole area involved. Further rendering coats should not be applied over soft, friable material, or where the existing render is greater than 15mm thickness.

1. Locate cracks greater than 0.5mm which may be active.

2. Arrange for measurement of cracks.

3. Assess the wall for movement

4. Sound the whole wall areas to detect detached areas of render or substrate.

5. Checking the construction details for effectiveness and suitability for increased render thickness.

6. Random hammer tests to ensure the render is fully bonded to the substrate.

Ensure substrate is free from dirt, grease or any other contamination.

Clean and treat substrate with weber CL150. Leave to cure for a minimum of 48 hours to ensure growing moss and unseen spores are killed.

Re-set details utilising a 10mm profile bead, fix with weberend bead adhesive.

Apply weberend aid at 2-3mm with a stipple finish using a brush or loaded roller. Allow to cure for at least 48 hours.

Apply choice of new render and finish as desired, bearing in mind that the entire render system must not exceed a total thickness of 25mm – this includes the old render layers, layer of weberend aid, and new render.

We recommend using a through-colour

If preferred, you could instead use a base coat render such as weberend OCR and then add a

If you have any questions or would like assistance, please contact our technical team:

Our technical team is available Monday to Friday, 8:30am until 5.00pm.

Find all our products near you in more than 1,000 branches